Cooling Tower Water Treatment: Essential Best Practices & Tips

- Share

- Issue Time

- Oct 15,2025

Summary

Discover essential cooling tower water treatment best practices to prevent scale, corrosion, and biological growth—ensuring efficient, reliable, and long-lasting HVAC operation.

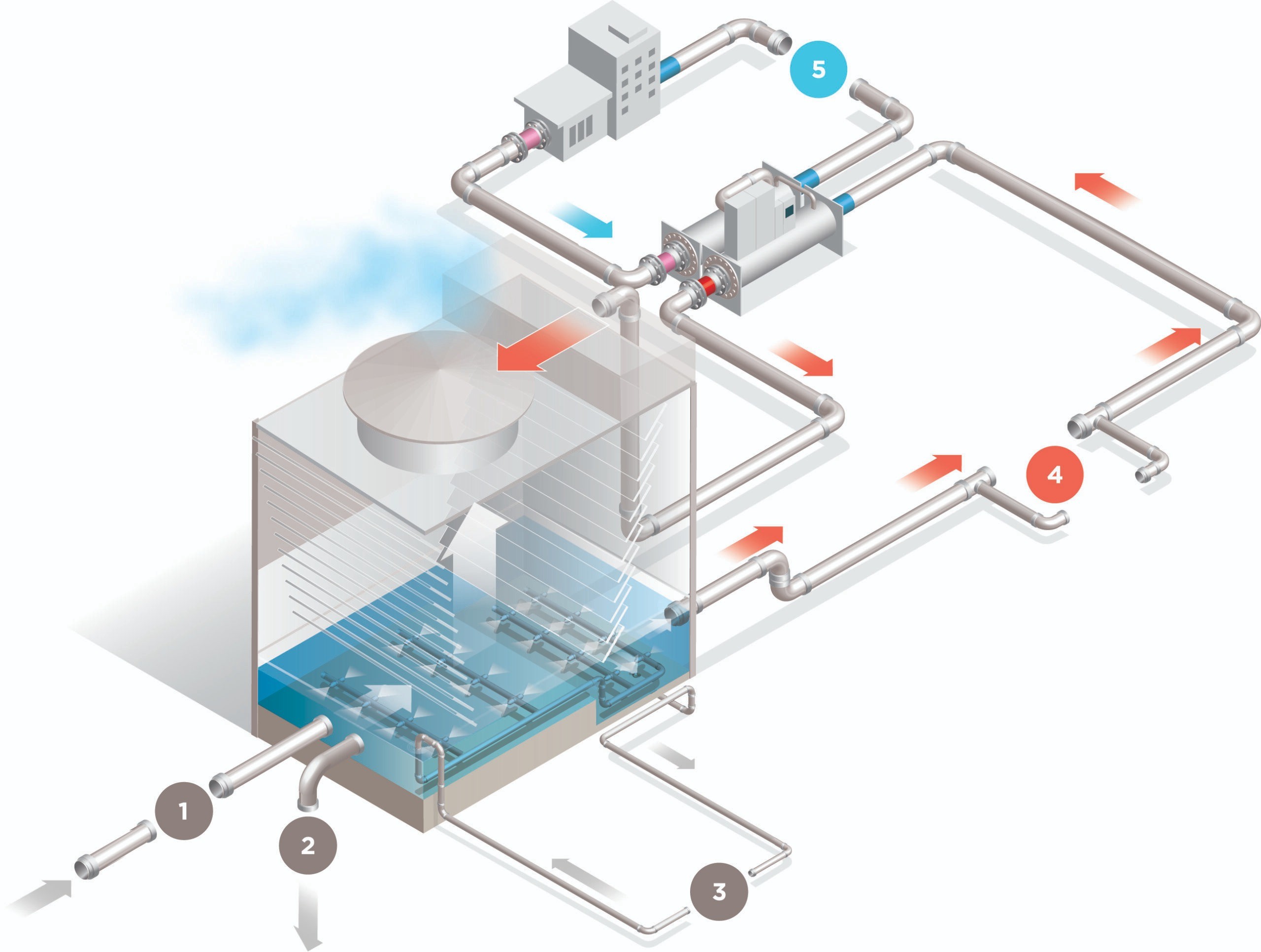

Cooling towers play a vital role in commercial and industrial HVAC systems, helping remove heat from chillers and maintain proper cooling performance. However, without proper water treatment, cooling towers can quickly become breeding grounds for scale, corrosion, and biological contamination—all of which reduce efficiency and system lifespan.

In this article, we’ll explore why cooling tower water treatment is essential, the common challenges it addresses, and the best practices to ensure your system runs safely and efficiently.

1. Why Cooling Tower Water Treatment Matters

Cooling towers continuously circulate large volumes of water, releasing heat as it evaporates. As the water evaporates, dissolved minerals, salts, and impurities become more concentrated. Over time, this can lead to:

● Scaling of heat exchange surfaces, reducing efficiency.

● Corrosion, damaging metal components and piping.

● Biological growth, including algae and bacteria like Legionella.

If not properly addressed, these issues can lead to wasted energy, unplanned downtime, and safety risks, significantly increasing operating costs.

2. Common Problems in Cooling Tower Water Systems

To understand the importance of water treatment, let's first review the most common water-related challenges in cooling towers:

A. Scale Formation

Minerals such as calcium and magnesium form hard deposits on heat transfer surfaces. Just 1 mm of scale can reduce heat transfer efficiency by up to 10%.

B. Corrosion

Untreated water can cause oxygen pitting and galvanic corrosion, damaging coils, basins, and piping. Corrosion can also introduce rust particles that can clog filters and valves.

C. Microbial Growth

Warm, nutrient-rich water provides an ideal growth environment for bacteria, fungi, and algae. If left uncontrolled, this can lead to biofilm formation and Legionnaires' disease, a serious health hazard.

D. Dirt and Sediment Accumulation

Dirt, dust, and airborne particles can settle in the basin, reducing system capacity and clogging filters.

3. Key Components of Cooling Tower Water Treatment

An effective cooling tower water treatment program includes three key control areas:

1. Scale Control

● Use chemical antiscalants (phosphonates or polymers) to prevent mineral deposits.

● Maintain an appropriate concentrate cycle (the ratio of dissolved solids in the recirculating and makeup water).

● Perform regular blowdowns, removing the concentrate and replacing it with fresh makeup water.

2. Corrosion Prevention

● Maintain a pH between 6.8 and 8.5, depending on the system materials.

● Add corrosion inhibitors, such as molybdates or nitrite compounds, to protect metal surfaces.

● Ensure tight sealing in the piping system and minimize air leaks to prevent oxygen ingress.

3. Biocontrol

● Regularly apply biocides (oxidizing and non-oxidizing) to control microbial growth.

● Use UV-C disinfection systems or ozone generators as environmentally friendly alternatives.

● Regularly clean and inspect the cooling tower basin and fill material.

4. Best Practices for Cooling Tower Water Treatment

To maximize performance and extend the life of your cooling system, follow these best practices:

✅ Regular Monitoring and Testing

Check water quality parameters—pH, conductivity, hardness, and microbial levels—weekly or as needed. Automated sensors and controllers can continuously track water quality and adjust chemical dosages accordingly.

✅ Routine Cleaning and Maintenance

Clean the basin, filters, drift eliminators, and fill sections regularly to remove sediment and algae buildup.

✅ Optimize Blowdown Operations

Blowdowns that are too frequent waste water; too infrequent can lead to scaling. Find the right balance based on water quality and system load.

✅ Use a Pretreatment System

In areas with hard or mineral-rich water, install a water softener or reverse osmosis (RO) system to remove hardness before the water enters the cooling tower.

✅ Keep Detailed Records

Keep a log of all water treatment operations, test results, and maintenance. This helps identify trends and ensures compliance with safety regulations, such as ASHRAE 188 (Legionella Control).

5. The Role of Automation in Modern Cooling Tower Management

In 2025 and beyond, a growing number of commercial buildings will adopt smart water treatment systems that leverage IoT sensors, cloud analytics, and automated dosing controls.

These advanced systems can:

● Detect changes in water chemistry in real time.

● Automatically adjust chemical dosages.

● Send alerts about abnormalities or maintenance needs.

● Optimize energy and water use, improving sustainability.

Automation ensures consistent water quality while reducing manual labor and operational risks.

6. Environmental and Regulatory Compliance

Environmental sustainability is a growing concern. Cooling tower operators must comply with local regulations regarding discharge water quality and Legionella control.

Implementing environmentally friendly treatment solutions (such as biodegradable inhibitors, ozone disinfection, and micro-chemical dosing systems) can help reduce the environmental footprint while ensuring compliance with health and safety standards.

Conclusion

Effective cooling tower water treatment is crucial to maintaining the efficiency, lifespan, and safety of heating, ventilation, and air conditioning (HVAC) systems. By proactively treating and monitoring to control scaling, corrosion, and microbial growth, facility managers can ensure reliable system operation and avoid costly repairs or downtime.

At Aurashu, we specialize in providing energy-efficient, reliable, and environmentally friendly HVAC water treatment solutions. Whether you operate a commercial office, factory, or data center, our team of experts can help you design and maintain a customized water treatment solution tailored to your system's unique needs.

Protect Your Cooling Tower with Expert Water Treatment Solutions

Contact Aurashu HVAC Experts today to schedule a water quality assessment and learn how to optimize your cooling tower performance for long-term savings and safety.