How Does a Water-Cooled Screw Chiller Work?

- Share

- Issue Time

- Nov 26,2025

Summary

Learn how a water-cooled screw chiller works—from its refrigeration cycle to screw compressor and heat exchange—and why it provides reliable, efficient cooling for industrial and commercial HVAC systems.

How Does a Water-Cooled Screw Chiller Work?

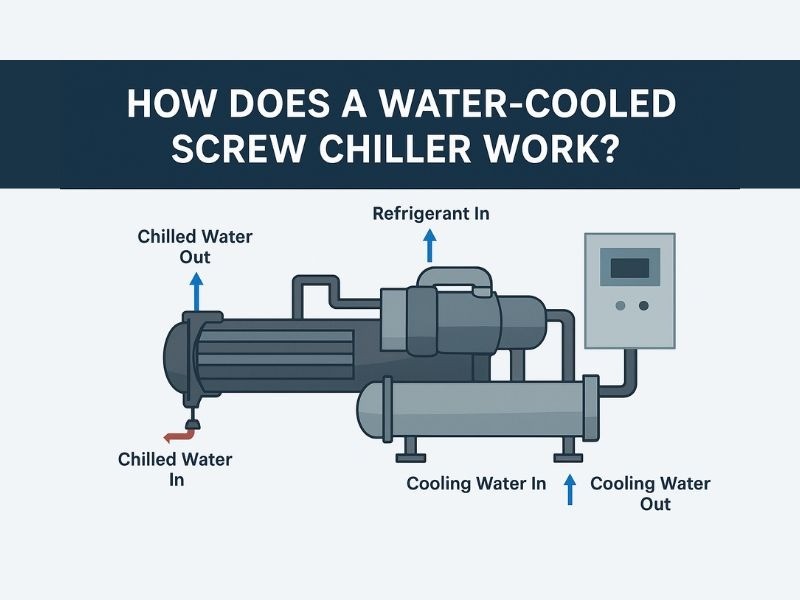

Water-cooled screw chillers are widely used in industrial and commercial HVAC systems due to their stable performance, high efficiency, and large cooling capacity. These systems combine the advantages of water-cooled heat dissipation with the stability of screw compressor technology. To better understand why they perform so well, let's take a detailed look at the working principle of a water-cooled screw chiller.

1. The Basic Working Principle

Like other mechanical refrigeration systems, water-cooled screw chiller units also utilize the vapor compression refrigeration cycle. This cycle includes four main stages:

Evaporation → Compression → Condensation → Expansion

Through this continuous process, the chiller unit absorbs heat from the building or industrial process and dissipates the heat to the outdoors through a cooling tower.

2. How the Screw Compressor Works

The core component of a water-cooled screw chiller unit is the screw compressor—a positive displacement compressor that uses two intermeshing helical rotors.

Main functions of the screw compressor:

● Draws in low-pressure refrigerant vapor from the evaporator

● Compresses the vapor to a high-pressure, high-temperature state

● Provides stable and continuous cooling with minimal vibration

Characteristics of screw compressors:

● High reliability

● Excellent part-load performance (especially under variable speed drive (VSD) control)

● Low noise and low maintenance requirements

Its continuous compression process makes the screw chiller an ideal choice for medium to large cooling loads.

3. Main Components of a Water-Cooled Screw Chiller

1) Evaporator

The evaporator is the starting point of the refrigeration process:

● Warm return water from the building enters the evaporator.

● The refrigerant inside absorbs heat from the water.

● The refrigerant evaporates into a gaseous state.

● The cooled water returns to the HVAC system.

This provides a stable supply of chilled water for cooling coils or industrial processes.

2) Screw Compressor

After evaporation, the low-pressure refrigerant vapor is compressed by the screw compressor.

The compression process:

● Increases pressure

● Raises temperature

● Prepares the refrigerant for heat dissipation

3) Water-Cooled Condenser

The refrigerant dissipates heat here:

● High-temperature refrigerant vapor enters the condenser.

● Cooling tower water absorbs the heat.

● The refrigerant condenses into a liquid state.

Water-cooled condensers typically use a shell-and-tube design, offering high heat transfer efficiency.

4) Expansion Valve

The expansion valve reduces the pressure of the refrigerant:

● High-pressure liquid refrigerant flows through the valve.

● The pressure drops sharply.

● The refrigerant cools down again.

The refrigerant can now re-enter the evaporator to absorb heat again.

4. The Cooling Tower Loop

Water-cooled screw chiller units work in conjunction with a cooling tower.

The function of the cooling tower is to:

● Receive hot water from the condenser

● Dissipate heat into the atmosphere through evaporation

● Return the cooled water to the condenser

This circulation ensures stable heat dissipation and improves system efficiency.

5. Step-by-Step Operation of a Water-Cooled Screw Chiller

1. Warm building/process water enters the evaporator.

2. The refrigerant absorbs heat → the water is cooled.

3. The screw compressor compresses the refrigerant vapor.

4. The high-temperature vapor flows into the condenser.

5. Cooling tower water absorbs heat and dissipates it to the outside.

6. The refrigerant condenses into a high-pressure liquid.

7. The expansion valve reduces the pressure.

8. The refrigerant returns to the evaporator → the cycle repeats.

This continuous operating process ensures stable cooling 24/7 without interruption.

6. Why Water-Cooled Screw Chillers Are Preferred

✔ Stable performance under heavy load

Even in demanding industrial environments, screw compressors provide uninterrupted and balanced operation.

✔ High energy efficiency

Water cooling + screw compression = lower operating costs.

✔ Quiet and smooth operation

Low vibration, low noise, and fewer moving parts, thus reducing maintenance requirements.

✔ Suitable for industrial and commercial use

For example:

● Manufacturing plants

● Data centers

● Hospitals

● Office buildings

● Hotels

● Large HVAC systems

✔ Supports low GWP refrigerants

Helps businesses meet 2025 environmental and energy regulations.

Conclusion

Water-cooled screw chiller units operate through a precise and efficient refrigeration cycle driven by a screw compressor and assisted by a cooling tower. Their reliability, energy efficiency, and superior performance under heavy loads make them one of the most trusted cooling solutions for industrial and commercial HVAC applications.

Whether you are upgrading an existing facility or designing a new system, water-cooled screw chiller units offer long-term value, stability, and environmental benefits.