How are the modules connected and controlled?

- Share

- Issue Time

- Nov 4,2025

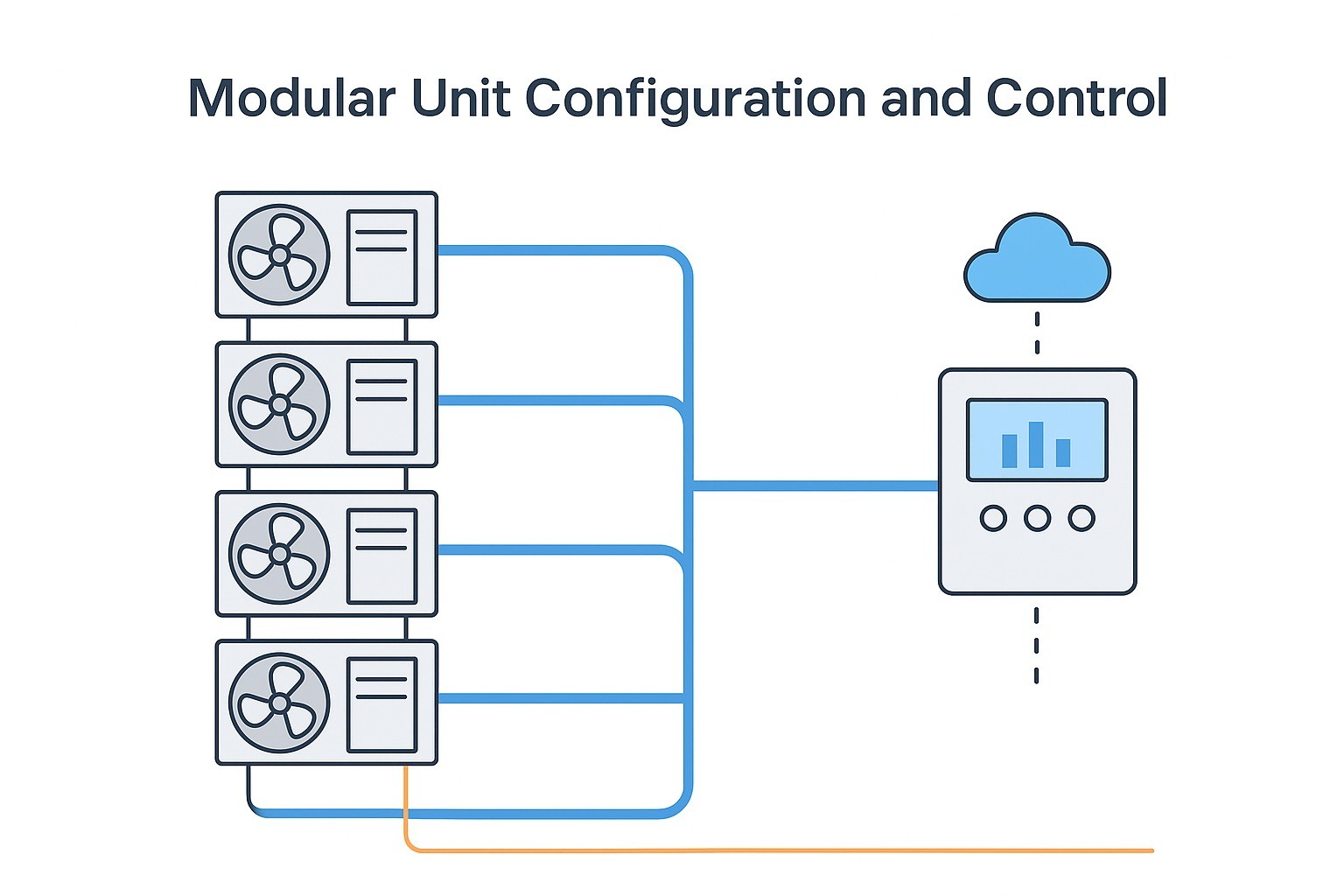

Aurashu’s modular air-cooled cold (hot) water units are designed for flexible configuration and intelligent connectivity. Each module operates as an independent refrigeration system with its own compressor, evaporator, and condenser, but multiple modules can be linked together through a shared water piping network and communication bus. The hydraulic system typically connects modules in parallel using quick couplings and standardized flanges, enabling seamless capacity expansion or reduction as needed.

In terms of control, the system adopts an integrated microcomputer or PLC-based centralized control platform. Through a communication protocol (such as Modbus or BACnet), all modules share operational data, automatically balance load distribution, and coordinate start-stop sequencing to achieve optimal efficiency. The master control unit monitors temperature, pressure, and flow in real-time and adjusts each module’s output accordingly.

This intelligent linkage allows up to 16 modules to run synchronously, achieving precise temperature control, energy saving, and fault redundancy. It ensures high stability, easy scalability, and smart management for commercial and industrial applications.