What is a Water-Cooled Centrifugal Chiller?

- Share

- Issue Time

- Dec 22,2025

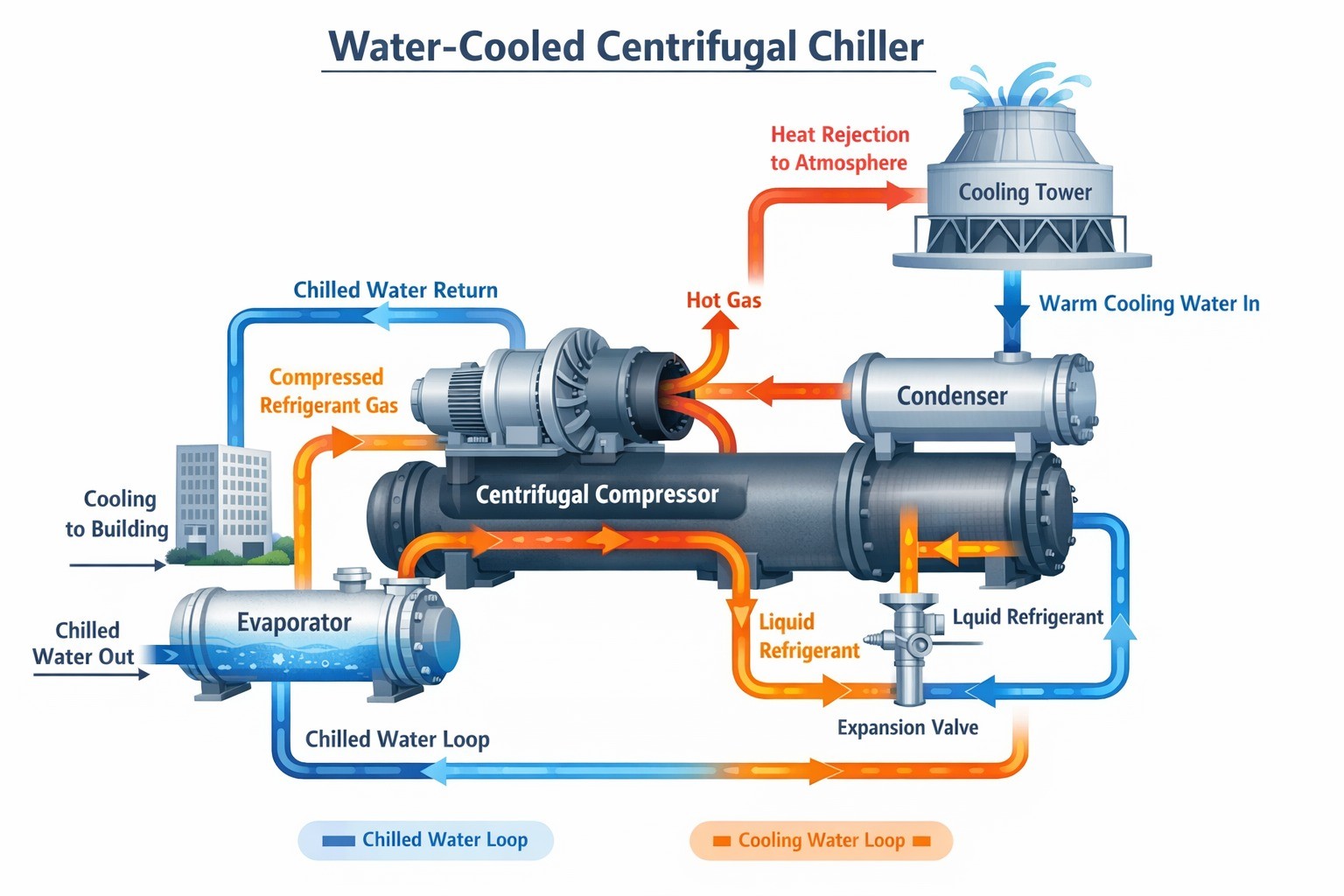

A Water-Cooled Centrifugal Chiller is a high-capacity central cooling system widely used in large commercial, industrial, and infrastructure HVAC applications. It uses a centrifugal compressor driven by an electric motor to compress refrigerant vapor, while cooling is achieved through a water-cooled condenser connected to a cooling tower. Compared with air-cooled systems, water-cooled centrifugal chillers offer higher efficiency, quieter operation, and superior performance for large cooling loads.

Core Working Principle

In a water-cooled centrifugal chiller, low-pressure refrigerant vapor enters the centrifugal compressor, where it is accelerated by high-speed impellers and converted into high-pressure vapor. This vapor then flows into the condenser, where cooling water absorbs the heat and rejects it through a cooling tower. The refrigerant condenses into liquid form, passes through an expansion device, and evaporates again in the evaporator by absorbing heat from the chilled water loop, completing the refrigeration cycle.

Aurashu water-cooled centrifugal chillers are engineered with advanced aerodynamic compressor design, optimized refrigerant flow paths, and high-efficiency heat exchangers to ensure stable performance under continuous heavy-duty operation.

High-Capacity and Energy Efficiency Advantages

Water-cooled centrifugal chillers are especially suitable for large cooling capacities, typically ranging from several hundred to several thousand tons of refrigeration. Their efficiency improves significantly at part load, which is critical for real-world building operation.

Aurashu integrates high-efficiency centrifugal compressors, premium evaporators and condensers, and intelligent control algorithms to deliver:

Excellent COP and IPLV performance

Reduced electricity consumption during partial load operation

Stable cooling output under varying ambient and load conditions

This makes Aurashu centrifugal chillers ideal for energy-conscious projects seeking long-term operational savings.

Reliability and Long Service Life

Designed for continuous operation, water-cooled centrifugal chillers are known for their durability and reliability. Aurashu units feature:

Robust compressor construction with fewer mechanical wear components

Precision-machined heat exchangers for consistent heat transfer

Advanced protection systems for pressure, temperature, flow, and motor safety

These features ensure long service life, reduced downtime, and dependable operation in mission-critical facilities.

Intelligent Control and System Integration

Aurashu water-cooled centrifugal chillers support advanced microprocessor-based control systems that enable:

Precise capacity modulation

Automatic load matching

Remote monitoring and fault diagnostics

Seamless integration with BMS and plant-level control systems

Multiple chillers can be staged intelligently to optimize efficiency, enhance redundancy, and ensure stable cooling delivery across large HVAC systems.

Typical Applications

Due to their high efficiency and large capacity, Aurashu water-cooled centrifugal chillers are widely used in:

Airports and transportation hubs

Large office complexes and commercial centers

Data centers and cloud computing facilities

Hospitals and medical campuses

Industrial plants and manufacturing facilities

District cooling and energy stations

Aurashu provides customized engineering solutions, tailoring capacity, control logic, and system configuration to meet project-specific requirements.

Aurashu Value and Customization Capability

As an experienced HVAC equipment manufacturer, Aurashu offers:

Customized capacity and refrigerant options

Flexible control strategies and energy optimization solutions

Professional technical support from design to commissioning

Compliance with international efficiency and safety standards

Aurashu water-cooled centrifugal chillers are not just products, but complete cooling solutions designed to support long-term system performance and sustainable building operation.