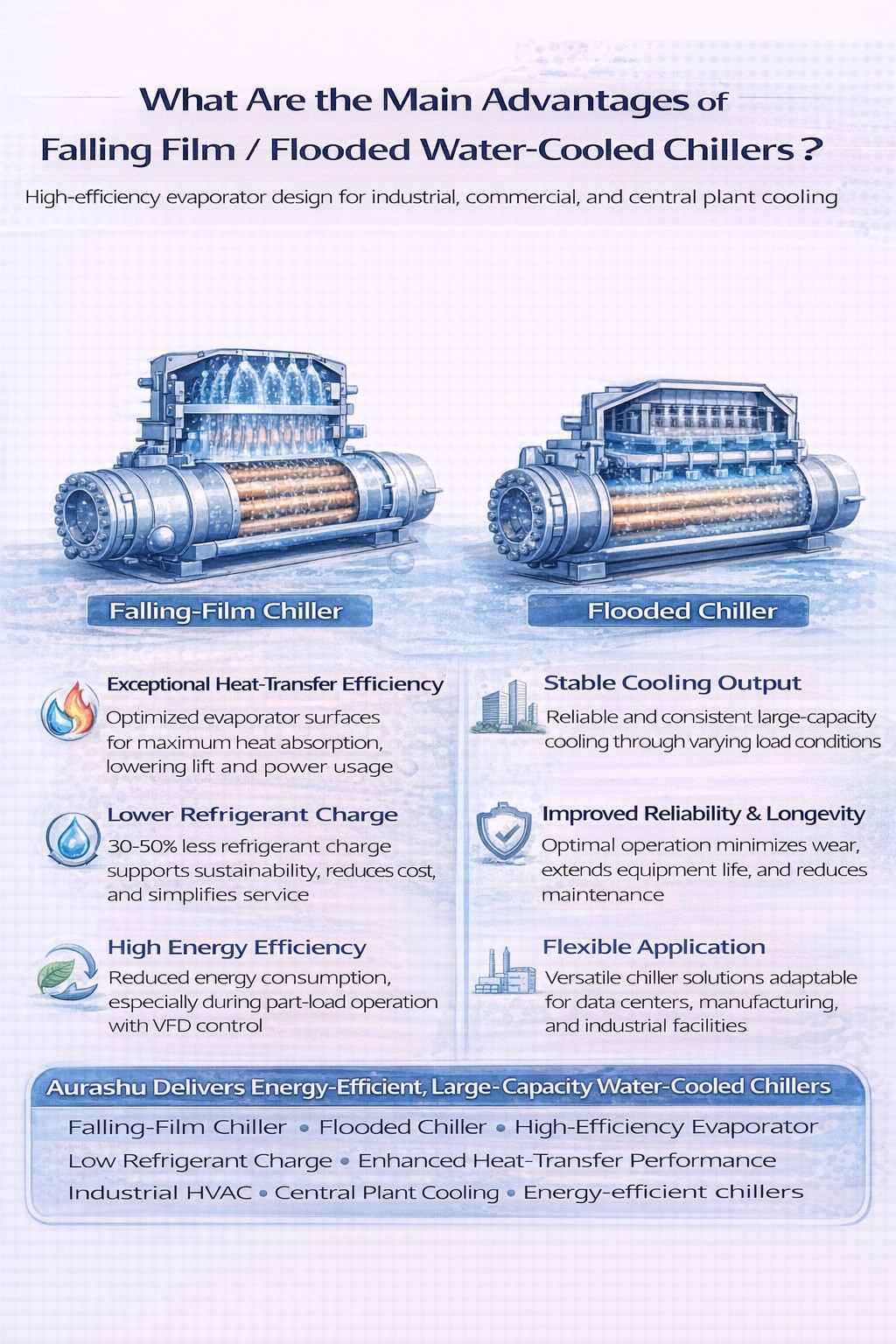

What Are the Main Advantages of Falling Film / Flooded Water-Cooled Chillers?

- Share

- Issue Time

- Dec 26,2025

Falling film and flooded water-cooled chillers offer several high-value advantages that make them ideal for large-capacity, high-efficiency central cooling applications. Both evaporator types are engineered to maximize heat-exchange performance, reduce operating costs, and enhance long-term system reliability. Aurashu integrates optimized falling-film and flooded designs with advanced control logic, precision oil-management, enhanced heat-transfer tubing, and high-efficiency compressors to achieve superior operational performance in commercial and industrial environments.

1. Exceptional Heat-Transfer Efficiency

The primary advantage of both falling-film and flooded chillers lies in their enhanced heat-exchange capabilities. Falling-film evaporators use a thin refrigerant film over the tube surface, dramatically improving evaporation efficiency while reducing the total refrigerant charge. Flooded evaporators, on the other hand, submerge the tube bundle, maintaining maximum thermal contact even under fluctuating loads. This results in superior system COP, stable performance, and higher IPLV values.

2. Lower Refrigerant Charge (Especially Falling Film)

Sustainability and regulatory compliance drive the need for lower refrigerant volumes. Falling-film chillers can reduce refrigerant charge by 30–50% compared to conventional flooded units. This reduction minimizes operating cost, simplifies leak management, and supports the transition to newer low-GWP refrigerants. Aurashu’s optimized distribution system ensures an even, controlled refrigerant film for efficient operation with minimal charge.

3. High Energy Efficiency & Part-Load Performance

Both falling-film and flooded systems excel in energy savings, especially when combined with high-efficiency centrifugal, screw, or magnetic-bearing compressors. The enhanced evaporator efficiency allows the compressors to operate at lower lift and reduced power input. With Aurashu’s intelligent VFD and adaptive control algorithms, the chiller maintains exceptional part-load performance, supporting 24/7 mission-critical environments.

4. Stable Cooling Output for Large-Capacity Systems

Flooded evaporators are particularly valued for their stability in high-capacity central plants. Because the tubes are fully submerged, heat transfer remains consistent even when the load varies. This provides the operational reliability needed for industrial cooling, district energy, and large commercial buildings. Aurashu designs both evaporator types to maintain constant film thickness, optimized refrigerant distribution, and maximum surface utilization.

5. Improved System Reliability & Longer Equipment Life

Thanks to optimal heat-exchange efficiency and reduced compressor workload, these chillers experience less mechanical stress. Flooded systems enhance lubrication consistency, while falling-film units reduce refrigerant foaming and liquid entrainment. Aurashu’s precision oil-return design, micro-channel distribution system, and corrosion-resistant tube materials greatly extend equipment lifespan and reduce maintenance frequency.

6. Lower Operating Costs & Reduced Maintenance Needs

High efficiency translates directly into lower energy consumption. The even thermal load on compressors prevents premature wear, and the reduced refrigerant mass lowers service cost. Aurashu integrates self-cleaning design options, anti-fouling solutions, and real-time predictive diagnostics to ensure low long-term operating expenses.

7. Flexible Application Across Many Industries

Because of their strong efficiency and reliability characteristics, falling-film and flooded chillers are widely used in commercial buildings, data centers, industrial cooling, chemical production, pharmaceutical facilities, and district cooling systems. Aurashu customizes evaporator type, compressor configuration, tube material, and control logic based on project requirements.